Sauƙaƙan busasshen turmi samar da layin CRM2

Cikakken Bayani

Gabatarwa

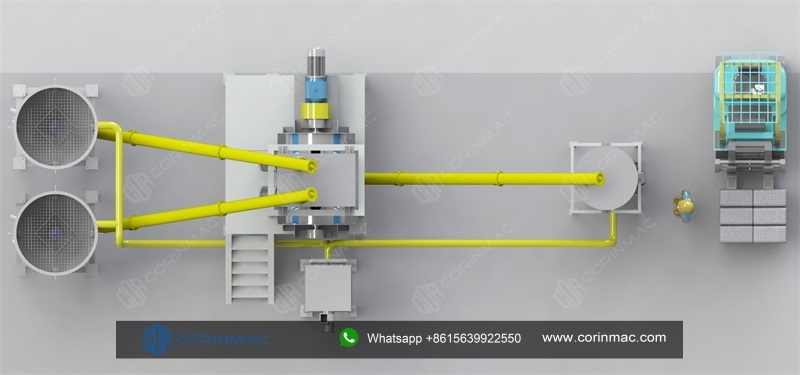

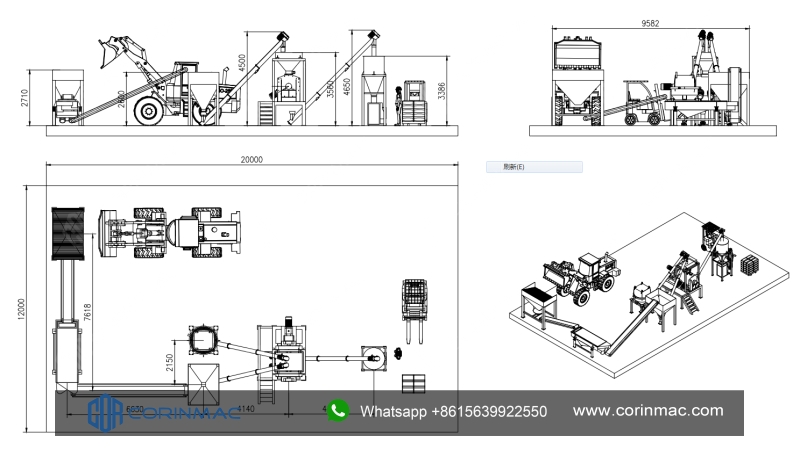

Sauƙaƙan busasshen turmi samar da layin CRM2

Layin samar da sauƙi CRM2 ya dace da samar da busassun turmi, foda mai ɗorewa, plastering turmi, skim gashi da sauran kayan foda.Dukkanin kayan aikin yana da tsari mai mahimmanci, ƙananan sawun ƙafa.Ya sanye da injin sauke buhun ton don sarrafa albarkatun ƙasa da rage ƙarfin aiki na ma'aikata.Yana ɗaukar hopper mai aunawa don daidaita sinadarai ta atomatik don inganta ingantaccen samarwa.Dukan layin na iya gane sarrafawa ta atomatik.

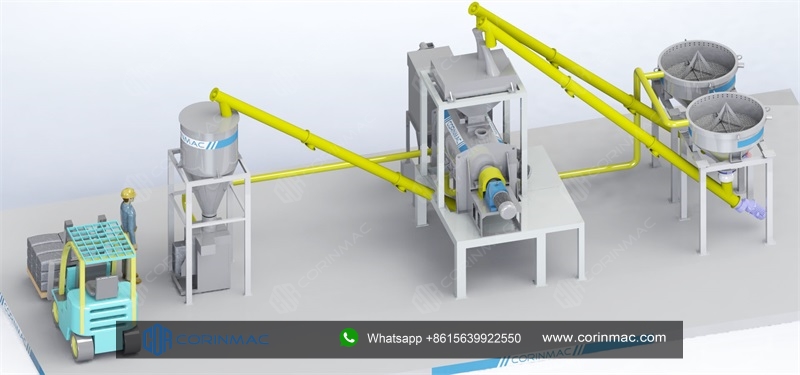

Tsarin tsari shine kamar haka

Screw conveyor

Screw conveyor ya dace da isar da kayan da ba su da ɗanɗano kamar busassun foda, siminti, da sauransu. Ana amfani da shi don jigilar busassun foda, siminti, foda gypsum da sauran albarkatun ƙasa zuwa mahaɗin layin samarwa, da jigilar samfuran gauraye zuwa ga mahaɗin. da ƙãre samfurin hopper.Ƙarshen ƙarshen ƙwanƙwasa mai ɗaukar hoto wanda kamfaninmu ya samar yana sanye da kayan abinci na ciyarwa, kuma ma'aikata suna sanya albarkatun kasa a cikin hopper.An yi dunƙule da farantin karfe na gami, kuma kauri ya dace da kayan daban-daban da za a kai.Dukansu ƙarshen mashin mai ɗaukar hoto sun ɗauki tsarin rufewa na musamman don rage tasirin ƙura a kan ɗaukar nauyi.

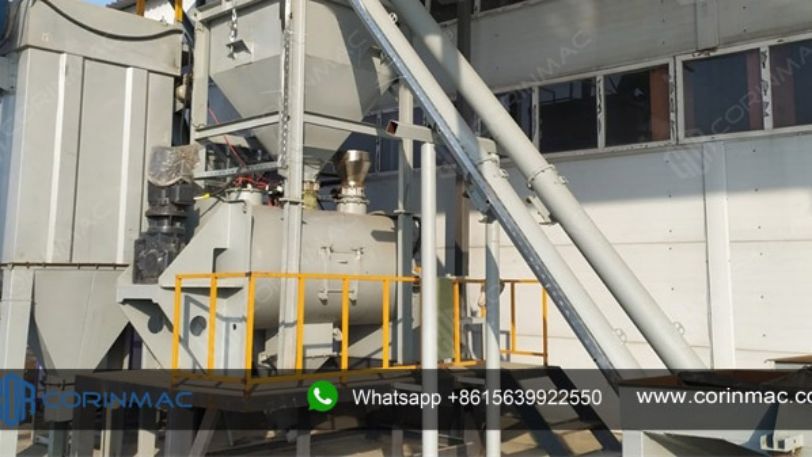

Busassun turmi mahaɗin

Mai haɗa busassun turmi shine ainihin kayan aiki na busasshen samar da turmi, wanda ke ƙayyade ingancin turmi.Ana iya amfani da mahaɗar turmi daban-daban bisa ga nau'ikan turmi daban-daban.

Single shaft garma share mahautsini

Fasahar mahaɗar rarar garma ta fi fitowa daga Jamus, kuma ita ce mahaɗa da aka saba amfani da ita a manyan layukan samar da busassun foda.Mahaɗin raba garma ya ƙunshi babban silinda na waje, babban shaft, rabon garma, da hannaye rabon garma.Jujjuyawar babban igiya tana motsa ƙwanƙwasa masu kama da plowshare don jujjuya cikin sauri mai ƙarfi don fitar da kayan don motsawa cikin sauri a cikin kwatance biyu, don cimma manufar haɗuwa.Gudun motsawa yana da sauri, kuma an shigar da wuka mai tashi a bangon silinda, wanda zai iya tarwatsa kayan da sauri, don haka hadawa ya fi dacewa da sauri, kuma haɗin haɗin yana da girma.

Single shaft garma share mahautsini (babban fitarwa kofa)

Single shaft garma share mahautsini (super high gudun)

Hopper mai nauyi

Raw Material Weighing Hopper

Tsarin aunawa: Daidaitaccen kuma barga, mai sauƙin sarrafawa.

Yin amfani da madaidaicin na'urori masu auna firikwensin, ciyarwar mataki, da na'urori masu auna firikwensin bellow na musamman don cimma ma'auni mai ma'ana da tabbatar da ingancin samarwa.

Bayani

Wurin aunawa ya ƙunshi hopper, firam ɗin ƙarfe, da na'ura mai ɗaukar nauyi (ƙasan ɓangaren ma'aunin yana sanye da dunƙule fitarwa).Ana amfani da kwandon auna ko'ina a cikin layukan turmi daban-daban don auna sinadarai kamar su siminti, yashi, tokar tashi, calcium mai haske, da calcium mai nauyi.Yana da fa'idodi na saurin batching mai sauri, daidaiton ma'auni mai girma, ƙarfin juzu'i, kuma yana iya ɗaukar kayan girma daban-daban.

Ƙa'idar aiki

Ma'aunin kwandon kwandon ne rufaffiyar, bangaren na kasa sanye yake da magudanar ruwa, sannan na sama yana da tashar ciyarwa da tsarin numfashi.Ƙarƙashin umarnin cibiyar kulawa, ana ƙara kayan bi da bi zuwa bin ma'auni bisa ga tsarin da aka saita.Bayan an gama aunawa, jira umarnin don aika kayan zuwa mashigin lif na guga na hanyar haɗin gwiwa na gaba.Dukkanin tsarin batching ana sarrafa shi ta hanyar PLC a cikin majalisar kulawa ta tsakiya, tare da babban matakin sarrafa kansa, ƙaramin kuskure da ingantaccen samarwa.

Hopper samfurin

Ƙarshen samfurin hopper ɗin silo ne na rufaffiyar silo wanda aka yi da faranti na gami don adana samfuran gauraye.saman silo yana sanye da tashar ciyarwa, tsarin numfashi da na'urar tattara ƙura.Bangaren mazugi na silo an sanye shi da na'urar bugu mai huhu da na'urar karya baka don hana toshe kayan a cikin hopper.

Injin shirya jakar bawul

Dangane da bukatun abokan ciniki daban-daban, zamu iya samar da nau'ikan kayan tattarawa uku, nau'in mai takaici, nau'in iska da iska mai iyo don zabar ku.Modulun awo shine ainihin ɓangaren injin ɗaukar jakar bawul.Mai shirya mai amfani, mai kula da kayan sarrafawa da aka yi amfani da shi a cikin injin kayan aikinmu sune duk kewayon farko, da kuma kuskuren auna, da kuma kuskuren auna.

Gudanar da majalisar

Kayan aikin da aka jera a sama shine ainihin nau'in nau'in layin samarwa.

Idan ya zama dole don rage ƙura a wurin aiki da kuma inganta yanayin aiki na ma'aikata, za a iya shigar da ƙananan ƙurar ƙurar bugun jini.

A takaice, za mu iya yin daban-daban tsare-tsaren da kuma jeri bisa ga bukatun.